The Lincoln Cooper CRX-10iA/L Air-Cooled Factory Demo Welding Cobot Cart addresses the critical skilled welder shortage affecting manufacturing industries worldwide with an innovative collaborative robotic solution. This revolutionary welding automation system combines Lincoln Electric's unparalleled welding expertise—refined since 1895 through more than a century of continuous innovation—with cutting-edge collaborative robot technology specifically engineered to meet today's manufacturing challenges. Designed from the ground up to integrate seamlessly into existing production environments, the Cooper Cart represents a transformative approach to welding automation that balances advanced technological capabilities with practical usability and affordability. This air-cooled collaborative robot system delivers precision welding performance while maintaining the flexibility and accessibility required by modern manufacturing operations, making sophisticated automation technology accessible to businesses of all sizes seeking to enhance productivity and maintain competitive advantage.

Compare to New Lincoln Welding Collaborative Cobot AD2489-8 and AD2489-16 Full 5 Year Lincoln Electric Warranty Included

At the core of the Cooper CRX-10iA/L system is the revolutionary Cooper App, a groundbreaking software solution developed by Lincoln Electric to democratize robotic welding programming. This intuitive application features a user-centric interface with comprehensive on-screen instructions that guide operators through each step of the weld programming process, effectively eliminating the traditional learning curve associated with robotic systems. The Cooper App's innovative approach to human-machine interaction enables even first-time users to create high-quality, consistent welds without specialized training, dramatically reducing implementation time and maximizing return on investment. This powerful software works in perfect harmony with the industrial-grade FANUC CRX collaborative robot and Lincoln Electric's advanced Power Wave R450 welding power source to create an integrated ecosystem that continuously monitors and optimizes welding parameters for superior quality and productivity.

The Lincoln Cooper CRX-10iA/L welding cobot system is engineered with comprehensive support infrastructure to ensure customer success throughout the automation journey. Lincoln Electric provides extensive resources including complimentary online training programs, specialized in-person training classes, and access to an unmatched support network comprising 275 dedicated technical sales representatives and 115 specialized robot technicians with deep expertise in welding automation applications. Safety remains paramount in the Cooper Cart design philosophy, with the collaborative robot architecture specifically engineered to enable direct human-robot interaction without requiring extensive guarding or safety barriers. This collaborative approach to welding automation creates a flexible production environment where human workers and robotic systems can safely share workspace, maximizing operational efficiency while maintaining the highest safety standards. The Cooper CRX-10iA/L represents Lincoln Electric's commitment to developing accessible automation solutions that address real-world manufacturing challenges while delivering the quality, reliability, and support that have defined the Lincoln Electric brand for generations.

- Intuitive Cooper App with step-by-step programming guidance requiring no specialized training.

- Industrial-grade FANUC CRX collaborative robot designed for direct human-robot interaction.

- Advanced Lincoln Electric Power Wave R450 power source with comprehensive weld monitoring.

- Air-cooled torch system optimized for general manufacturing applications.

- Collaborative robot architecture eliminating need for extensive safety guarding.

- Extensive support infrastructure including free online training resources.

- Access to nationwide network of technical representatives and robot specialists.

- Purpose-built solution addressing the skilled welder shortage affecting manufacturing.

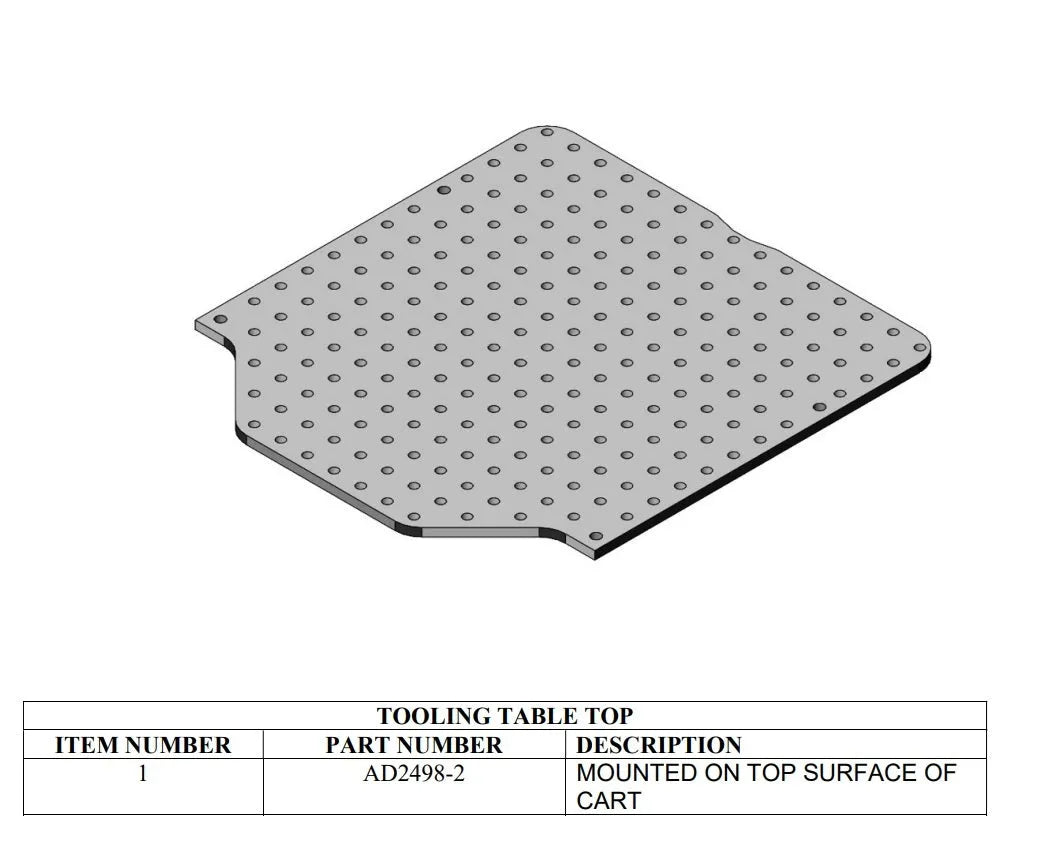

- Compact, mobile cart design enabling flexible deployment across production environments.

| Robot Model | FANUC CRX-10iA/L Collaborative Robot |

| Power Source | Lincoln Electric Power Wave R450 |

| Programming Interface | Cooper App with Intuitive Step-by-Step Guidance |

| Weld Control | Power Wave Advanced Process Monitoring |

| Cooling System | Air-Cooled Configuration |

| Available Resources | FREE Online Training In-Person Training Classes 275 Technical Sales Representatives 115 Specialized Robot Technicians |

| Collaborative Design | Engineered for Safe Direct Human-Robot Interaction Reduced Guarding Requirements Force-Limiting Technology Advanced Safety Monitoring |