The Lincoln Cooper CRX-10iA/L Aluminum Welding Cobot Cart represents a revolutionary advancement in accessible welding automation, designed to address the critical shortage of skilled welders across industries. This innovative collaborative robot system combines Lincoln Electric's century-plus welding expertise with cutting-edge robotic technology to create a mobile, user-friendly solution that enables direct human-robot interaction without traditional safety barriers. The system's portability allows for flexible deployment throughout manufacturing facilities, maximizing return on investment through adaptable application to diverse welding tasks.

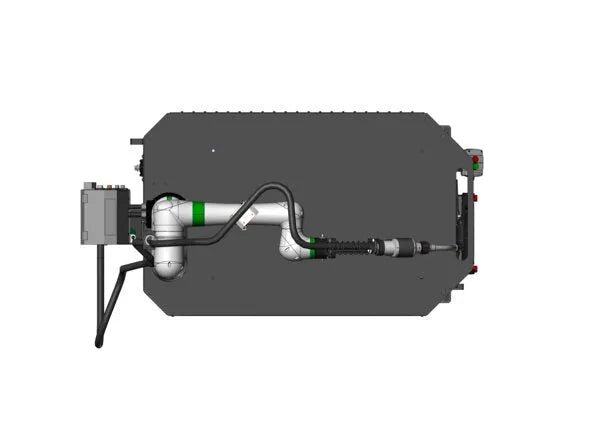

At the core of this system is the integration of FANUC's proven CRX collaborative robot technology with Lincoln Electric's advanced Power Wave R450 power source and specialized aluminum welding capabilities. The AutoDrive SA high-performance aluminum servo torch solution addresses the unique challenges of robotic aluminum welding, ensuring consistent wire feeding and reliable arc starts that are crucial for high-quality aluminum fabrication. This purpose-built combination delivers exceptional weld quality and productivity, enabling manufacturers to maintain competitive advantages despite workforce limitations.

The Cooper Cart system emphasizes reliability and operational longevity, with components selected and configured specifically for demanding robotic applications. The Power Wave R450 carries a 5-year warranty, while the AutoDrive SA and Magnum PRO Water-Cooled components are backed by 1-year warranties. The FANUC CRX robot itself features the same industrial-grade technology proven across rigorous applications for over three decades, with an impressive eight-year zero maintenance guarantee on critical components. This comprehensive solution is supported by extensive training resources, including free online training, in-person classes, and access to Lincoln Electric's extensive network of technical representatives and robot technicians, ensuring users can maximize the system's capabilities and return on investment.

- AutoDrive SA high-performance aluminum servo torch solution ensuring consistent wire feeding and reliable arc starts.

- Industrial FANUC CRX collaborative robot designed for safe, direct human interaction without traditional safety barriers.

- Lincoln Electric Power Wave R450 power source with advanced software control for superior weld quality and productivity.

- Mobile cart design enabling flexible deployment throughout manufacturing facilities for diverse applications.

- Comprehensive warranty coverage including 5 years for Power Wave R450 and 1 year for specialized components.

- FANUC eight-year zero maintenance guarantee on robot motors, reducers, sensors, cables, and grease.

- Extensive support ecosystem including free online training, in-person classes, and technical assistance network.

- Water-cooled torch system supporting extended duty cycles for demanding production environments.

- Purpose-built integration optimized specifically for aluminum welding applications.