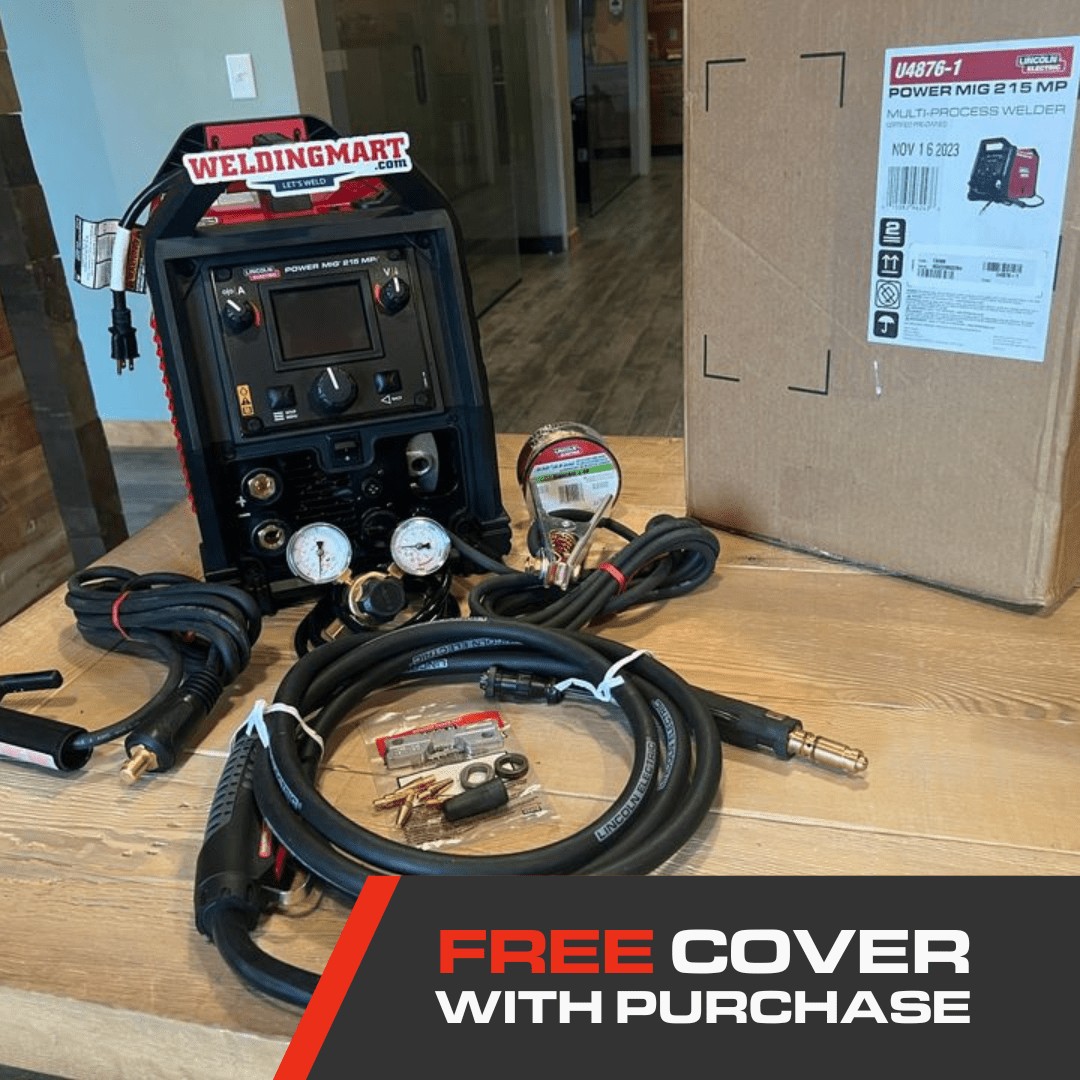

The Lincoln Power MIG 215 MPi delivers professional welding performance in a compact, dual-voltage system — perfect for shops and field use alike. This used Lincoln Power MIG 215 MPi - U4876-1 comes with a full 3 year factory warranty is a versatile multi-process welding system engineered to deliver exceptional performance and reliability for general fabrication, small contractor operations, and repair applications. This comprehensive welding solution combines user-friendly technology with robust construction to create a platform that excels across MIG, TIG, Stick, and Flux-Cored processes without compromising on performance or durability. The thoughtfully designed ergonomic case with strategically placed lift points maximizes mobility throughout the workshop environment, while the intuitive interface dramatically simplifies both the initial setup process and ongoing selection of optimal welding parameters.

The Power MIG 215 MPi showcases Lincoln's commitment to operational versatility with its dual input voltage capability, accommodating both 120V and 230V power sources to ensure functionality in virtually any working environment. The integrated TIG-ready design features a built-in TIG solenoid and foot pedal adapter that eliminates additional installation requirements when transitioning to TIG welding applications. The system's robust and reliable wire drive mechanism ensures consistent wire feeding performance across various wire types and diameters, delivering optimal welding results regardless of the selected process or material. The implementation of Lincoln's proprietary Ready.Set.Weld® Technology provides intelligent parameter recommendations that simplify setup procedures, allowing operators to achieve optimal results with minimal configuration effort.

The Power MIG 215 MPi incorporates advanced user interface technologies that enhance both operational efficiency and weld quality. The innovative ArcFX® Technology provides immediate visual feedback illustrating how parameter adjustments affect weld characteristics, enabling operators to optimize settings before beginning production work. The comprehensive memory capability allows frequently used parameter configurations to be saved and quickly recalled, significantly reducing setup time for recurring applications. Despite its impressive multi-process capabilities and advanced features, the Power MIG 215 MPi maintains exceptional portability at just 48 pounds, making it an ideal solution for applications requiring mobility without sacrificing welding performance or process versatility.

Quick Specs: Weld Thickness Max 3/8", Max Amperage 200-300 Amps, Input Power: 115V / 230V

- Comprehensive multi-process capability supporting MIG, Flux-Cored, Stick, and DC TIG welding.

- Flexible dual input voltage compatibility (120V/230V) for operation with any common power supply.

- Ergonomic case design with multiple lift points enhancing workplace mobility and handling.

- Integrated TIG-ready configuration with built-in solenoid and foot pedal adapter eliminating setup complexity.

- Industrial-grade wire drive system ensuring consistent feeding performance and optimal weld quality.

- Ready.Set.Weld® Technology providing intelligent parameter recommendations for simplified setup.

- ArcFX® Technology delivering immediate visual feedback on parameter effects for optimized settings.

- Comprehensive memory capability for efficient storage and recall of preferred welding parameters.

- Exceptional portability with lightweight 48-pound design facilitating workplace mobility.

Machine Inputs & Outputs

| Phase 1: Input Voltage #1 (Voltage/Phase/Hertz) | 120/1/60 |

| Phase 1: Rated Output #1A (Current/Voltage/Duty Cycle) | MIG: 105A/19.25V/40% 80A/18V/100% |

| Phase 1: Rated Output #1B (Current/Voltage/Duty Cycle) | TIG: 130A/15.2V/40% 100A/14V/100% |

| Phase 1: Rated Output #1C (Current/Voltage/Duty Cycle) | Stick: 80A/23.4V/40% 60A/22.4V/100% |

| Phase 1: Input Current at Max Rated Ouput #1 (Current) | 22A |

| Phase 1: Input Voltage #2 (Voltage/Phase/Hertz) | 230/1/60 |

| Phase 1: Rated Output #2A (Current/Voltage/Duty Cycle) | MIG: 215A/24.8V/30% 120A/20V/100% |

| Phase 1: Rated Output #2B (Current/Voltage/Duty Cycle) | TIG: 175A/17V/30% 110A/14.4V/100% |

| Phase 1: Rated Output #2C (Current/Voltage/Duty Cycle) | Stick: 175A/27V/30% 110A/24.4V/100% |

| Phase 1: Input Current at MAX Rated Output #2 (Current) | 29A |

| Dimensions (H x W x D) | 15.08 in x 10.88 in x 23.14 in (383 mm x 276 mm x 588 mm) |

| Net Weight | 48 lbs (21.8 kg) |

| Machines Processes | Stick (SMAW) Flux-Cored (FCAW) TIG (GTAW) MIG (GMAW) |

| Number of Operators per Machine | 1 |

| Input Voltage | 120/230 |

| Input Current | 120V: 15A, 230V: 15.9A |

| Input Hertz | 60 |

| Input Phase | 1 |

| Input Power | 120/230/1/60 |

| Mode Icon | CC/CV |

| Output Range | 120V: 20-140A DC 230V: 20-220A DC Max. OCV : 56V |

| Polarity | DC |

| IEC Rating | IP21S |

| Output Range by Mode | MIG: 20-220A |

| Machines Communication Technology | digital |

| Work Lead Connector Type | Dinse |

| Welding Gun Cable Assembly Length | Magnum PRO 175L |

| Work Cable Length | 10 FT |

| Spool Gun Compatible (Duty) | Light |

| UI type | TFT - Graphic |

| Wire Feeders Processes | MIG Flux Cored |

| Maximum Wire Thickness | 0.045 in (1.1 mm) |

| Minimum Wire Thickness | 0.025 in (0.6 mm) |

| Typical Application | Automotive Brewery Distillery General Fabrication Maintenance & Repair Repair Welding |

| Warranty | 3 Years |