Mathey Dearman Magnetized Pocket Level & Inclinometer (2X2.5 inch) - D208

$35.00Unit price /UnavailableMathey Dearman Fit-Up Pro Magnetized Torpedo Level & Inclinometer (10 inch) - D207

$85.00Unit price /UnavailableMathey Dearman Fit-Up Pro Magnetized Pipe Centering Finder w/Punch & Multi-Tool - D206

$85.00Unit price /UnavailableMathey Dearman Fit-Up Pro Small-Radius Marker up to 22 inch Circle - D209

$31.00Unit price /UnavailableMathey Dearman Large-Radius Marker up to 100 inch Circle - D211

$50.00Unit price /UnavailableMathey Dearman Medium-Radius Marker up to 50 inch Circle - D210

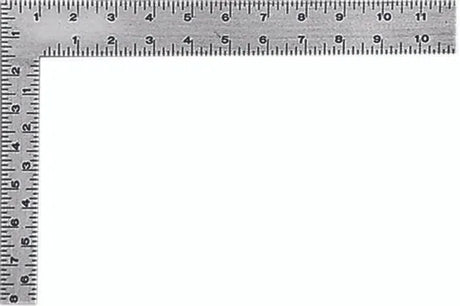

$43.00Unit price /UnavailableMathey Dearman Aluminum Framing Square 8-12"x1/16" / 203-305x1.6mm - D241

$50.00Unit price /UnavailableMathey Dearman Stainless 8-12"x1/16" / 203-305x1.6mm - D256

$80.00Unit price /UnavailableMathey Dearman Fit-Up Pro Mini Stainless Protractor - 4in / 102.4mm - DXX-250

$18.00Unit price /UnavailableMathey Dearman Fit-Up Pro Small Stainless Protractor - 18 & 12in / 457 & 305mm - DK-239

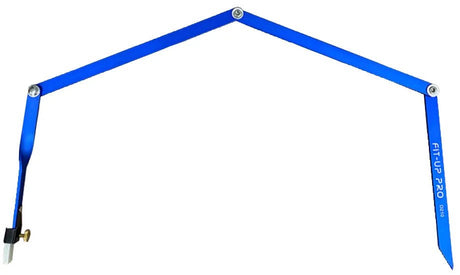

$87.00Unit price /UnavailableMathey Dearman Fit-Up Pro Large Aluminum Protractor - 48 & 36in / 1219 & 914mm - DK-100

$340.00Unit price /UnavailableMathey Dearman Fit-Up Prod Q.C. Welder's Gauge (English) - D253E

$56.00Unit price /UnavailableMathey Dearman Fit-Up Prod Q.C. Welder's Gauge (English) QTY. 10 - D253E-BOX

$500.00Unit price /UnavailableMathey Dearman 4"x7' / 102x2134mm - 3-26 inch Pipe Wrap - D177

$68.00Unit price /UnavailableMathey Dearman 4"x4' / 102x1219mm - 3-15 inch Pipe Wraps - D160

$31.00Unit price /UnavailableMathey Dearman 4" Wide Pipe Wrap - 1' Increment - D184

$12.50Unit price /UnavailableMathey Dearman 7" Wide Pipe Wrap - 1' Increments - D187

$18.00Unit price /Unavailable