Complex semi-automatic welding operations demand precision, consistency, and reliability across every production cycle. Lincoln Electric's revolutionary Weld Sequencer™ technology delivers an advanced digital solution that eliminates common welding errors including missed welds, misinterpreted work instructions, and incorrect procedure selection—issues that significantly impact manufacturing quality and productivity metrics. This comprehensive welding management system integrates seamlessly with Lincoln's industry-leading Power Wave platform to provide manufacturers with unprecedented process control capabilities, ensuring optimal weld quality and consistency across your entire production environment from part-to-part, operator-to-operator, and weld-to-weld.

The Weld Sequencer™ system transforms traditional welding operations through its sophisticated operator-friendly Human-Machine Interface (HMI) that systematically guides welders through complex assembly processes with exceptional clarity and precision. By implementing this advanced welding process control solution, manufacturing facilities can dramatically reduce quality variations, minimize rework requirements, and accelerate production throughput while maintaining comprehensive digital documentation for quality assurance and compliance purposes. The initial one-year license provides complete access to Lincoln Electric's proprietary welding sequence management technology, enabling organizations to immediately implement standardized welding procedures that deliver measurable improvements in operational efficiency and finished product quality.

Key Features

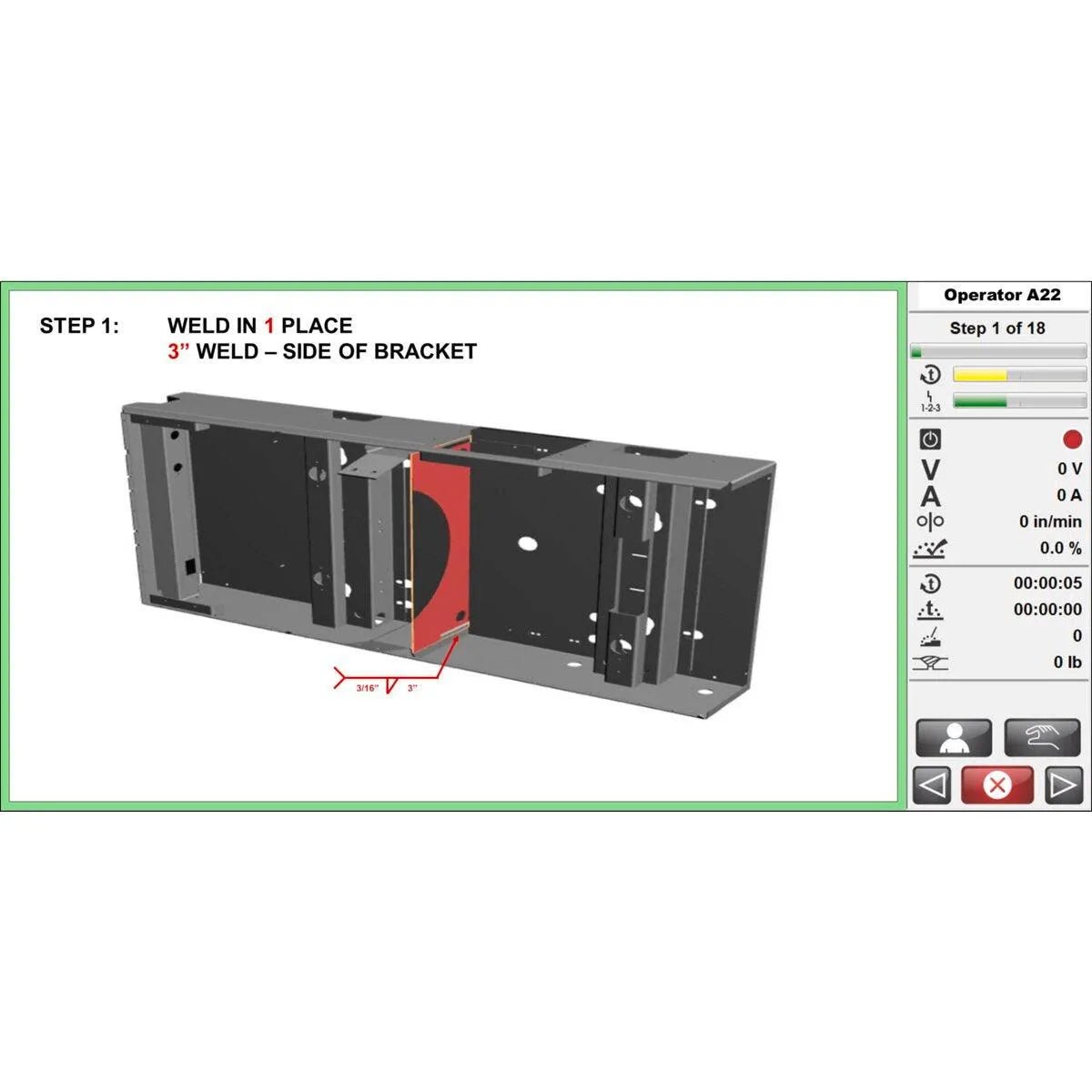

- Digitally Enhance Your Weld Instructions - Easy-to-follow graphic interface with step-by-step weld sequencing clearly guides operators through each step of the assembly process, simplifying complex work instructions.

- Automatic Control & Verification - Weld Sequencer™ automatically selects the correct welding procedure and parameters for each programmed weld with zero operator interaction, removing opportunities for operator error, improving quality, and saving valuable time by keeping operators focused on the workpiece rather than adjustments. Additionally, Weld Sequencer™ tracks and can automatically verify factors such as volume of weld deposited, weld duration, current, and voltage meet the programmed specifications and generate automatic alerts and reports to support QA/QC programs.

- Exclusive to Lincoln Electric Power Wave® Welding Systems