Achieve precision and efficiency in your welding projects with WeldingMart's industry-leading selection of pipe alignment and reforming tools. Our collection is designed to meet the demands of pipeline construction, metal fabrication, and maintenance professionals, offering tools that ensure accurate alignment and seamless reforming of pipes. With trusted brands like Mathey Dearman, we provide the quality and reliability you need for your most demanding jobs.

-

Mathey Dearman Boomer Assembly (Complete) for 1SA Saddle Machine - 03.0101.018

$190.00Unit price /UnavailableMathey Dearman Boomer Assembly Complete for 3SA Saddle Machine - 03.0103.020

$220.00Unit price /UnavailableMathey Dearman Chain (Only) for 1SA Boomer Assembly, 11.5' - 01.0577.002

$46.00Unit price /UnavailableMathey Dearman Boomer Assembly for MSA Pipe Beveler 1"-4" - 03.0100.024

$230.00Unit price /UnavailablePipe Alignment & Reforming Tools Collection

Our Pipe Alignment & Reforming Tool Categories

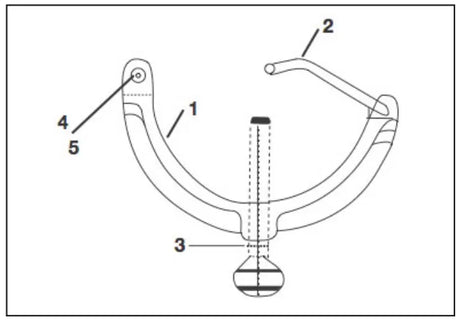

Pipe Alignment Clamps

Secure pipes in place with our durable and easy-to-use pipe alignment clamps. Available in various sizes to fit different diameters, these clamps help ensure perfect alignment for welding, improving the efficiency and accuracy of your work.

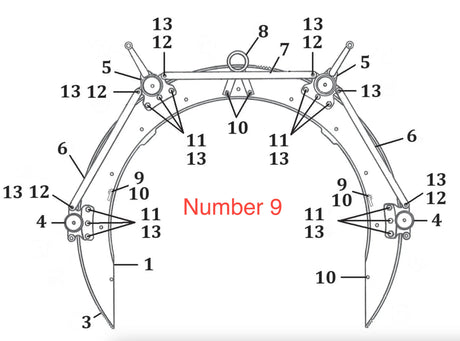

Reforming Clamps and Machines

Correct out-of-round pipes and ensure a perfect fit with our reforming clamps and machines. Built for heavy-duty use, these tools are ideal for high-precision applications in industries like oil and gas, construction, and metal fabrication. Explore top-performing options from Mathey Dearman.

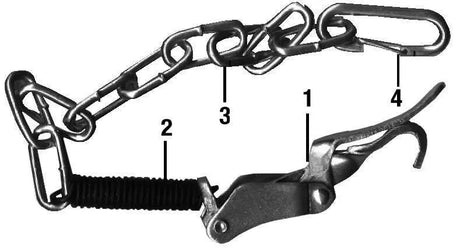

Chain Clamps

Designed for versatility, chain clamps allow for secure alignment of pipes of various shapes and sizes. These clamps are an essential tool for achieving precision and consistency in pipe fabrication projects.

Specialty Alignment Tools

For unique challenges, our collection includes specialty tools tailored for specific alignment and reforming tasks. Whether you need extra precision or heavy-duty support, our tools will help you get the job done right.

Why Choose WeldingMart for Pipe Alignment & Reforming Tools?

-

Top-Quality Brands

WeldingMart offers tools from industry leaders like Mathey Dearman, known for their innovative and durable solutions in pipe fabrication and alignment. -

Comprehensive Selection

Our extensive range of alignment and reforming tools ensures we have the right solution for any project, big or small. -

Built for Precision

Every tool in our collection is designed with precision and ease of use in mind, enabling professionals to achieve accurate results every time. -

Expert Support

Our knowledgeable team is available to assist you in selecting the perfect tools for your specific needs, ensuring you get the best performance and value. -

Long-Lasting Durability

Built with high-quality materials, our tools are engineered to withstand heavy-duty usage, offering long-term reliability and performance.

Applications for Pipe Alignment & Reforming Tools

- Pipeline Construction: Achieve perfect alignment and reforming for pipelines used in oil, gas, and water industries.

- Metal Fabrication: Ensure accuracy in structural welding projects with tools designed for precise alignment.

- Maintenance & Repairs: Simplify complex repair jobs with versatile alignment tools suitable for fieldwork and shop use.

- Boiler and Pressure Vessel Work: Equip yourself with tools capable of handling the demanding requirements of high-pressure systems.

Shop WeldingMart for Precision Pipe Alignment & Reforming Tools

At WeldingMart, we understand the importance of accuracy and efficiency in welding and fabrication. That’s why we offer a carefully curated collection of pipe alignment and reforming tools that meet the highest standards of performance and reliability. Whether you’re working on a large pipeline project or a small fabrication task, our tools will help you achieve professional-grade results.

Order Today

Browse our selection of alignment and reforming tools to elevate the precision and quality of your welding projects. With trusted brands like Mathey Dearman and expert support from WeldingMart, you’re equipped for success.Pipe Alignment & Reforming Tools | Precision Solutions for Welding Questions & Answers