Mathey Dearman Fit-Up Pro Magnetized Pipe Centering Finder w/Punch & Multi-Tool - D206

$85.00Unit price /UnavailableMathey Dearman Fit-Up Pro Large Aluminum Protractor - 48 & 36in / 1219 & 914mm - DK-100

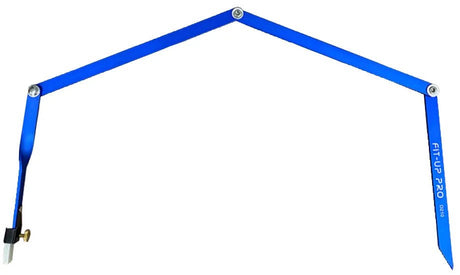

$340.00Unit price /UnavailableMathey Dearman Fit-Up Pro Small Stainless Protractor - 18 & 12in / 457 & 305mm - DK-239

$87.00Unit price /UnavailableMathey Dearman Fit-Up Pro Mini Stainless Protractor - 4in / 102.4mm - DXX-250

$18.00Unit price /UnavailableMathey Dearman Fit-Up Pro Spacing Wedges 4" x 3/4" / 1/4" / 102X19 X 6.4 mm QTY. 10 - D274-BOX

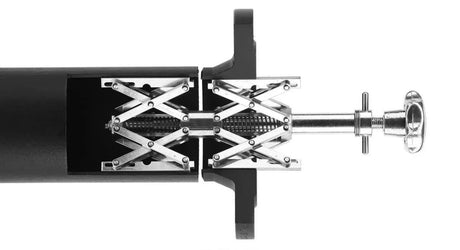

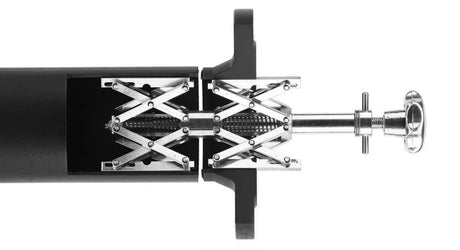

$150.00Unit price /UnavailableMathey Dearman Spider Clamp Stainless Steel 400 2"-6" 54-140mm - 400-1SS

$525.00Unit price /UnavailableMathey Dearman Spider Clamp Stainless Steel 400 4"-8" 85-220mm - 400-2SS

$810.00Unit price /UnavailableMathey Dearman Spider Clamp Stainless Steel 400 6"-14" 120-350mm - 400-3SS

$1,450.00Unit price /UnavailableMathey Dearman Magnetized Pocket Level & Inclinometer (2X2.5 inch) - D208

$35.00Unit price /UnavailableMathey Dearman Fit-Up Pro Pie Wedge 3 1/2"x1 1/2"x1/4" / 89x38x6.4mm - D272

$36.00Unit price /UnavailableMathey Dearman Fit-Up Pro Spacing Wedges 3 1/2"x1 1/2"x1/4" / 89x38x6.4mm QTY. 10 - D272-BOX

$310.00Unit price /UnavailableMathey Dearman Fit-Up Prod Q.C. Welder's Gauge (English) QTY. 10 - D253E-BOX

$500.00Unit price /UnavailableMathey Dearman Fit-Up Pro Protractors 8"x1 1/2"x1/4" / 203x38x6.4mm - D271

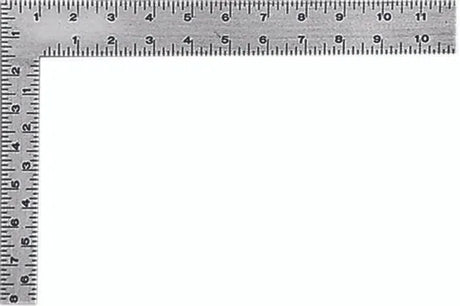

$50.00Unit price /UnavailableMathey Dearman Aluminum Framing Square 8-12"x1/16" / 203-305x1.6mm - D241

$50.00Unit price /UnavailableMathey Dearman Fit-Up Pro Spacing Wedges 8"x1 1/2"x1/4" / 203x38x6.4mm QTY. 10 - D271-BOX

$450.00Unit price /UnavailableMathey Dearman Fit-Up Pro Magnetized Torpedo Level & Inclinometer (10 inch) - D207

$85.00Unit price /UnavailableMathey Dearman Fit-Up Pro Small-Radius Marker up to 22 inch Circle - D209

$31.00Unit price /UnavailableMathey Dearman Spider Clamp Stainless Steel 400 8"-20" 180mm - 520mm - 400-4SS

$1,995.00Unit price /UnavailableMathey Dearman Spider Clamp Stainless Steel 400 400mm - 900mm - 400-5SS

$2,795.00Unit price /UnavailableMathey Dearman Fit-Up Pro Pie Wedge 4" x 3/4" / 1/4" / 102X19 X 6.4 mm - D274

$18.00Unit price /Unavailable

Mathey Dearman Beveling Machines & Equipment

Count on WeldingMart for excellent prices and shipping on Mathey Dearman pipeliner tools.

Pipe welding is a type of welding that requires welders to be at their best, ensuring precision welds in suboptimal conditions. That means pipeline welders are incredibly dependent on their equipment.

For more than 80 years, Mathey Dearman has been supplying pipeliners with the advanced tools and machinery they need. Ever since Chester A. Mathey sold his first pipe cutting and beveling machine in 1936, his company has been at the forefront of innovation and advancement. Acquiring the rights to the Dearman clamping systems in 1996 expanded their ability to help pipelining professionals do better work in less time. WeldingMart is an authorized dealer of Mathey Dearman piping tools and equipment for working on new construction, refineries, ships, municipal pipelines and other large-scale projects.

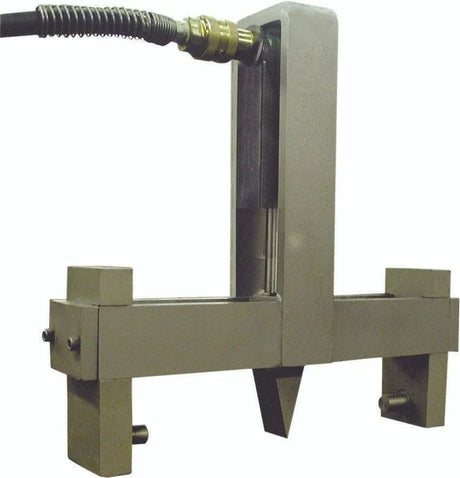

The Mathey Dearman pipe beveling machine continues to set the standard for quality piping work. Our selection includes jolli chain pipe cutting machines and saddle machine retrofit kits along with replacement parts and accessories. We also have a section of pipe alignment and reforming products. Find heavy-duty pipe clamps, chain clamps, ratchet cage clamps and other ways to keep pipes pointed the right way. You can fit them together with Mathey Dearman pipe stands, framing squares and other pipefitting tools. These long-lasting pipe tools give you great value that lasts, and our team has more than 50 years of industry knowledge to help you make the right choice.

Contact us today to learn more about this company's products and why they are worth your time and investment. Our staff of welding experts has worked in the field just like you and can share firsthand information about these products.

Mathey Dearman Beveling Machines & Equipment

Count on WeldingMart for excellent prices and shipping on Mathey Dearman pipeliner tools.

Pipe welding is a type of welding that requires welders to be at their best, ensuring precision welds in suboptimal conditions. That means pipeline welders are incredibly dependent on their equipment.

For more than 80 years, Mathey Dearman has been supplying pipeliners with the advanced tools and machinery they need. Ever since Chester A. Mathey sold his first pipe cutting and beveling machine in 1936, his company has been at the forefront of innovation and advancement. Acquiring the rights to the Dearman clamping systems in 1996 expanded their ability to help pipelining professionals do better work in less time. WeldingMart is an authorized dealer of Mathey Dearman piping tools and equipment for working on new construction, refineries, ships, municipal pipelines and other large-scale projects.

The Mathey Dearman pipe beveling machine continues to set the standard for quality piping work. Our selection includes jolli chain pipe cutting machines and saddle machine retrofit kits along with replacement parts and accessories. We also have a section of pipe alignment and reforming products. Find heavy-duty pipe clamps, chain clamps, ratchet cage clamps and other ways to keep pipes pointed the right way. You can fit them together with Mathey Dearman pipe stands, framing squares and other pipefitting tools. These long-lasting pipe tools give you great value that lasts, and our team has more than 50 years of industry knowledge to help you make the right choice.

Contact us today to learn more about this company's products and why they are worth your time and investment. Our staff of welding experts has worked in the field just like you and can share firsthand information about these products.