The Lincoln Frontier 400X Kubota is an advanced engine-driven welder/generator offering best-in-class arc performance, coupled with the latest welding innovation for maximum versatility on the jobsite. The multi-process capability of the Frontier 400X Lincoln Electric provides optimized CC and CV modes, plus specialized modes to support mechanized equipment and advanced GMAW applications including STT and pulse welding, making it ideal for pipe work. The Lincoln Frontier 400X simplifies the use of robotic systems, contributing to enhanced productivity. The next-gen display features enhanced operator-focused features like parameter memories, maintenance reminders, and optional PIN authorization. With Auto-Stop/Start technology and CrossLinc Technology, this machine helps reduce fuel costs, minimize engine wear, and allows output adjustment at the arc for improved productivity and weld quality. It also integrates well with pipe and TIG functions. Additionally, the Lincoln Electric Frontier 400X offers a Kubota Ready Pak, which includes everything required for efficient setup.

Seamless Interface: Digital Control of the Frontier 400X Lincoln Electric

This configuration is particularly beneficial for automated manufacturing processes, ensuring consistent quality. Embracing cutting-edge technology, the Frontier 400X boasts a next-generation digital user interface crafted to enrich the operator's welding experience. This state-of-the-art digital display integrates features like parameter memories and maintenance alerts, promoting seamless operation. Rugged enough for field conditions, this interface empowers operators to monitor and adapt various welding metrics, optimizing both productivity and weld quality. The interface is a pivotal tool for welders navigating remote job sites. The machine is built with rugged features for remote site operations, supporting dynamic teams in any location.

Innovative Technologies Revolutionize Welding with the Lincoln Electric Frontier 400X

Pioneering advancements in welding technology, the Lincoln Electric Frontier 400X integrates CrossLinc Technology and Auto-Stop/Start features, setting benchmarks for fuel efficiency and operational mastery, especially in pipe welding scenarios. Its fuel-efficient diesel engine is engineered to cut costs while maintaining unwavering power to sustain high productivity. Such automation primes the Frontier 400X to deliver superior weld quality and amplify job site efficiency. The welder's assembly line-like efficiency and cutting edge-technology help improve overall output. Incorporating state-of-the-art welding innovations and premium components, this welder machine stands as a top-tier option for welders and businesses seeking enhanced performance and reliability. In addition, the Frontier 400X is equipped with auxiliary power potential, offering up to 11 kW of continuous industrial-grade power, boosting site functionality. This supports component assembly and other energy-intensive manufacturing tasks.

- Multi-Process Capable - Offers up to 400 amps (IEC rated at 325 amps) of welding current for numerous welding and carbon arc gouging applications.

- Next-Gen Display - Bright, durable 7 in. digital user interface with save/recall memories and maintenance reminders.

- CrossLinc Enabled - Communicates through standard weld cable for voltage/current control at the arc without additional control cables.

- Fuel Efficient - Class-leading 20 US gal. (75.7 L) fuel tank with Auto-Stop/Start feature to prevent excessive idling.

- Auxiliary Power - Provides up to 11 kW of continuous three-phase power for industrial tools.

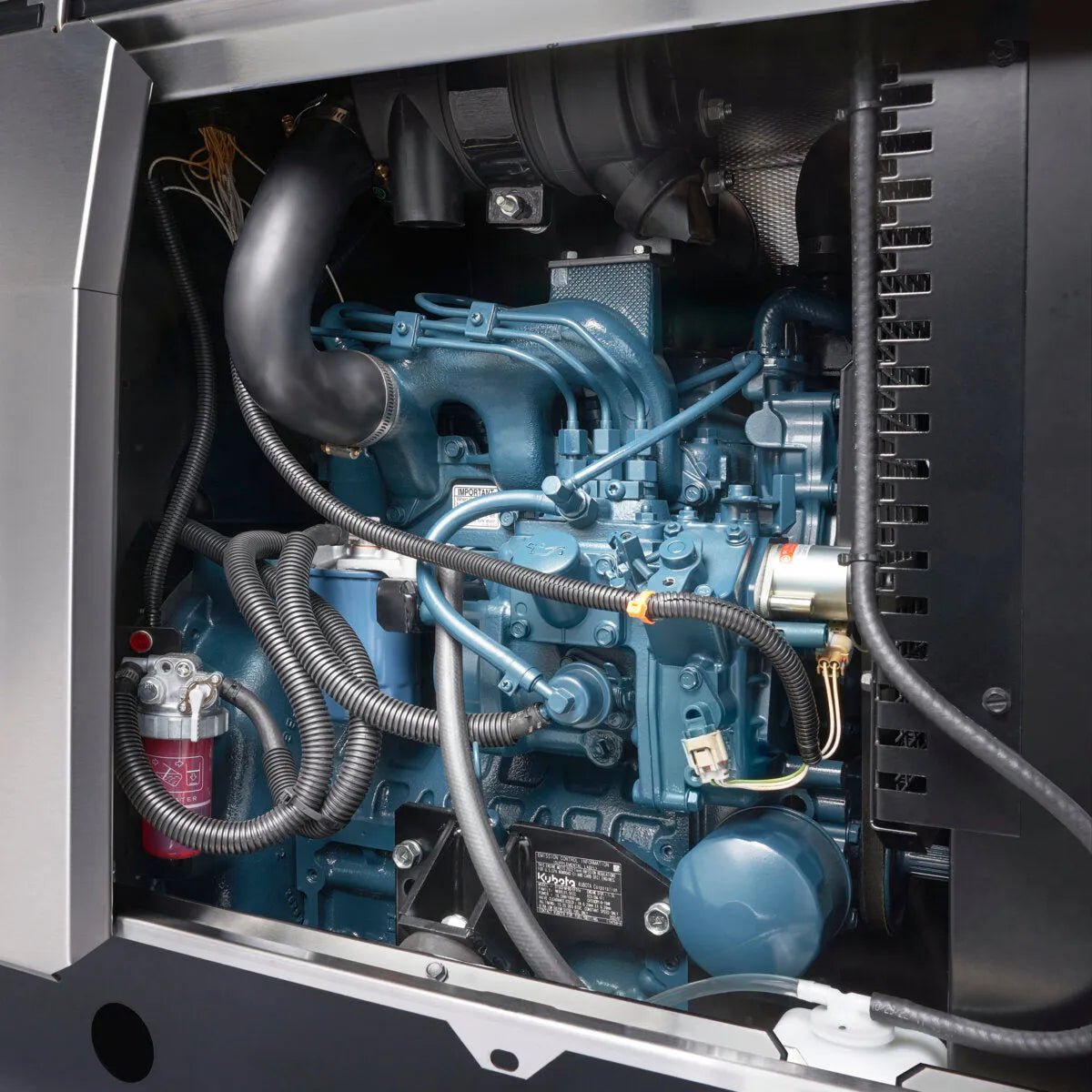

- Field-Proven Engine - Powered by a 24.8 hp Kubota diesel engine meeting EPA Tier 4 Final compliance.

- Trusted Reliability - Engineered for harsh conditions with 3-year warranty support.

Unmatched Performance and Safety in the Frontier 400X Kubota Delving into the Frontier 400X's Capabilities

Standing at the forefront of the welding industry, the Lincoln Electric Frontier 400X exemplifies exceptional productivity and unparalleled performance, making it a leading choice for industrial applications. Engineered with a robust 400 amps of DC output, this machine flawlessly adapts to diverse welding styles, including stick, MIG, and TIG applications. This powerhouse seamlessly facilitates operations on versatile materials such as steel and metal, ensuring superior weld quality. Designed for utmost safety and resilience, the Frontier 400X thrives under the rigorous demands of industrial and commercial sites. Choose from the reliable Frontier 400X Pipe Kubota or Frontier 400X Perkins engine options, enhancing both reliability and operational prowess.

FCAW and MIG Mastery: Leveraging the Lincoln Frontier 400X

Experience the forefront of welding technology with the Lincoln Electric Frontier 400X, advancing capabilities in FCAW and MIG processes. Designed to support advanced GMAW applications, including STT and pulse welding, for unrivaled versatility. Expertly accommodating shielded flux cored wires—ideal for both lightweight and heavy-duty tasks—this welder maximizes the welding cycle's efficiency, elevating productivity in manufacturing sites. By pioneering automated functionalities, it enhances electrode versatility, enabling welders to execute intricate fabrication, TIG, and robotic projects with precision.

Comprehensive Guide to Acquiring the Lincoln Electric Frontier 400X

Accessories such as custom systems and torches empower professionals to seamlessly tackle intricate projects, while the Kubota Ready Pak and 400X Kubota Ready deliver tailored solutions for distinctive needs. Include plasma cutters to handle diverse cutting needs efficiently. With Lincoln Electric's commitment to training and customer support, owning a Frontier 400X signifies investing in a welder capable of meeting current demands, including plasma cutting, and adapting to future challenges. With Lincoln Electric's commitment to training and customer support, owning a Frontier 400X signifies investing in a welder capable of meeting current demands and adapting to future challenges. Whether executing complex pipeline ventures or embarking on remote site operations, this welder guarantees unmatched weld integrity and productivity.