Browse top-performing welder generators that combine portable power with versatile welding capabilities. Ideal for remote jobsites and field repairs, these engine-driven machines deliver reliable performance for Stick, MIG, and TIG welding without needing grid electricity.

-

Lincoln Ranger 250 GXT Engine Driven Welder Kohler Electric Fuel Pump - K2382-4

$8,829.99Unit price /UnavailableLincoln Ranger 330MPX Low Hour Factory Demo Engine Driven Welder Generator Kohler - U3459-1

$8,399.00$9,849.99Unit price /UnavailableLincoln Ranger Air 260MPX Multi-Function Engine Drive - K5238-1

$14,955.22$16,994.00Unit price /UnavailableLincoln Ranger 330MPX EFI Low Hour Factory Demo Engine Driven Welder Generator Kohler - U4779-1

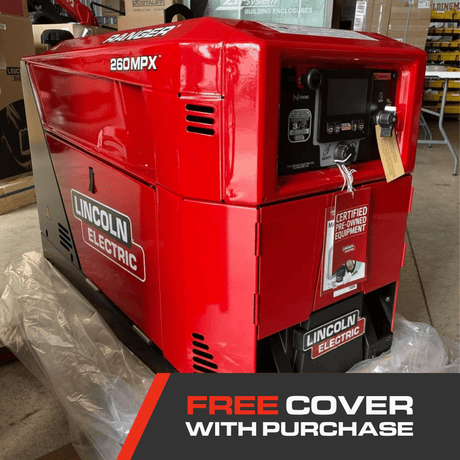

$8,999.00$10,689.99Unit price /UnavailableLincoln Ranger Air 260MPX Multi-Function Engine Drive Low Hour Factory Demo Model - U5238-1

$12,300.00$16,994.00Unit price /UnavailableLincoln Vantage 322 Engine Driven Welder Kubota - K2409-5

$22,423.00$25,431.00Unit price /UnavailableLincoln Bulldog 5500 Factory Demo Engine Driven Welder Kohler - U2708-2

$1,999.00$4,260.00Unit price /UnavailableLincoln Bulldog 5500 Engine Driven Welder Kohler - K2708-2

$3,867.73$4,260.00Unit price /UnavailableLincoln Cross Country 300 Kubota Engine Driven Welder - K4166-1

$27,247.77$30,963.00Unit price /UnavailableLincoln Ranger 260MPX Low Hour Factory Demo Engine Driven Welder - U3458-1

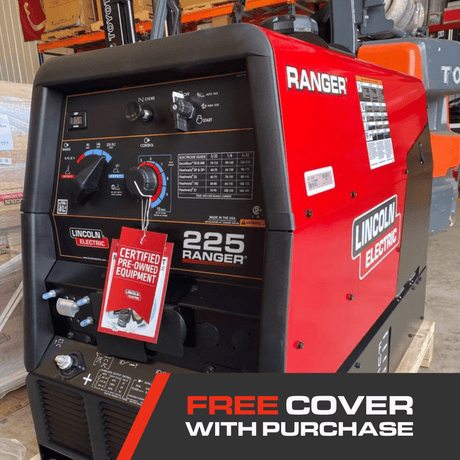

$6,899.00$8,129.99Unit price /UnavailableLincoln Ranger 225 Low Hour Factory Demo Engine Driven Welder Kohler - U2857-1

$5,699.00$6,849.99Unit price /UnavailableLincoln Ranger 250 GXT Low Hour Factory Demo Engine Driven Welder Kohler W/EFP - U2382-4

$6,499.00$8,829.99Unit price /UnavailableLincoln Factory Demo Frontier 400X Pipe Perkins Engine-Driven Welder/Generator - U3485-1

$21,699.00$26,378.00Unit price /UnavailableLincoln Eagle 10,000 PLUS Factory Demo Engine Driven Welder Kohler - U2343-3

$4,799.00$6,138.00Unit price /UnavailableThe Ultimate Guide to Welder Generators: Power, Versatility, and Portability

Introduction to Welder Generators

Definition and Purpose

A welder generator, also known as a generator welder or engine driven welder is a specialized piece of equipment that combines a generator and a welding machine into one unit. For those seeking enhanced portability, consider a portable welder generator. Gas powered welder generators are especially popular because they provide on-site power for welding operations without relying on grid electricity. Diesel welder generators are particularly noted for their durability and fuel efficiency. This makes them ideal for remote locations or construction sites where electrical access is limited or unavailable.

Importance in Welding Industry

The importance of welder generators in the welding industry cannot be overstated. They enable professionals and hobbyists to undertake fabrication, repairs, and maintenance in the field—anywhere power is needed. Their dual function of supplying electricity and performing welding tasks boosts productivity and versatility, making them indispensable for pipelines, emergency repairs, and infrastructure projects.

Features of Engine-Driven Welders

Portability

Engine-driven welders are designed for portability. Many models come with handles, wheels, or even trailer mounts, allowing operators to move them with ease between job sites. This feature is crucial for professionals who often work in outdoor or remote environments.

Welder generators are powered by various fuels, including gasoline, diesel, or propane. Engine-driven models provide flexibility and convenience on-site.

Welder generators are powered by various fuels, typically gasoline, diesel, or propane. Each option has advantages: - Gasoline: Readily available and good for lighter jobs. - Diesel welder: Preferred for heavy-duty, long-duration use due to fuel efficiency and durability. - Propane: Burns cleaner and is suited for indoor environments. Models like the Lincoln Ranger offer impressive outputs suitable for demanding jobs.

Power output also varies among welder generators, with different current ratings and auxiliary power outlets being offered. Among these, the Lincoln Electric models excel in performance. The engine allows them to run power tools and lights in addition to welding equipment. Engine driven welders include options for stick, MIG, and TIG welding.

Multi-Process Capabilities

Modern welding generators often feature multi-process capabilities such as Stick, MIG, and TIG welding in a single unit. This versatility lets users handle a wide variety of welding applications using one welding machine, reducing the need for separate equipment.

Leading Brands Comparison - Lincoln vs. Miller

When considering reliable brands, Miller and Lincoln Electric are industry leaders. Miller welders are known for their innovation, strong construction, and user-friendly controls. Lincoln Electric is respected for robust performance and broad service networks, making parts and service readily accessible for machine maintenance.

Unique Features of Popular Models

Popular Miller models, like the Miller Bobcat and Trailblazer 330 series, offer features like advanced arc control and lower noise operation. Lincoln's Ranger series, especially the Ranger 330MPX, is famous for its fuel efficiency and multi-process flexibility. Both offer auxiliary outlets so users can power tools or charge batteries on-site.

Selecting the Right Welder Generator

Factors to Consider

Choosing the best welder generator involves several factors: - Type of Welding: Select a model compatible with your preferred welding processes (Stick, MIG, TIG). - Power Output: Match the output to your project's needs. - Portability: Consider weight, wheel kits, and overall footprint. - Durability: Look for weather-resistant units with established reliability records.

Budget Considerations

Welder generator prices vary widely. Higher power and multi-process capabilities generally increase cost. Investing in a reputable brand often pays off in durability and long-term savings on machine repairs. Free shipping options and sales events can also reduce costs.

User Reviews

Reading user reviews helps identify real-world benefits and possible drawbacks. Pay attention to feedback on fuel efficiency, reliability, and ease of use to make a well-informed decision.

Conclusion and Recommendations

Summarizing Key Points

Engine-driven welder generators are essential for professionals who need mobile, self-sufficient welding solutions. With options powered by gasoline, diesel, or propane, and models offering multi-process capabilities, there is a solution for every need.

Final Thoughts on Welder Generators

Invest in tools and accessories that complement your generator welder. When searching for a welder generator for sale, focus on reputable brands like Miller and Lincoln, and consider your unique work requirements and budget. Whether you're a seasoned pro or an enthusiast, the right generator welder ensures you're equipped for any welding tasks, wherever the work takes you.

Welding Generators and Engine Driven Welders Questions & Answers