Understanding welding rod numbers is crucial for making informed decisions when selecting welding rods for different projects. This article focuses on the numerical designations of welding rods used in shielded-metal arc welding (SMAW), also known as "stick" welding. We'll break down the meaning behind these numbers and provide guidance on choosing the right rod for your needs.

What Do the First Two Numbers Indicate?

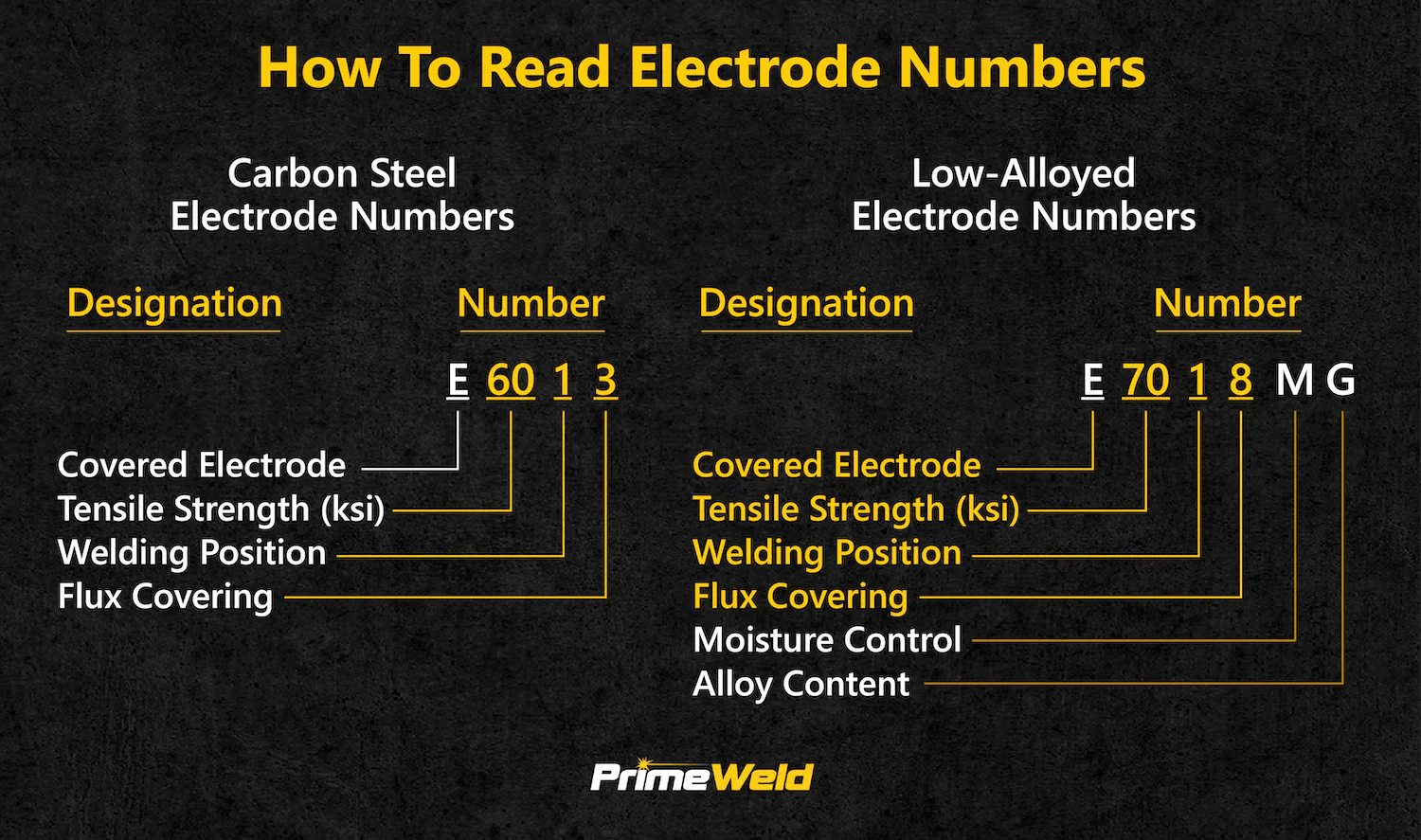

The first two (or sometimes three) numbers on a welding rod represent its tensile strength, measured in thousands of pounds per square inch (psi). This is based on the American Welding Society (AWS) designation.

For example:

- 7018 Rod: The "70" indicates a tensile strength of 70,000 psi.

- 11018 Rod: The "110" means it can withstand 110,000 psi.

- 6010 Rod: The "60" denotes a tensile strength of 60,000 psi.

Knowing the tensile strength helps ensure the weld can handle the necessary stress for your project.

What Does the Third Number Mean?

The third number on a welding rod indicates the positions in which it can be used. This is crucial for ensuring the rod is suitable for your welding position.

- "1": Can be used in all positions (flat, horizontal, vertical, and overhead).

- "2": Suitable for flat and horizontal positions.

- "4": Restricted to the flat position only.

For versatile welding needs, rods with a "1" are preferable due to their all-position capability.

What Does the Last Number Represent?

The last number provides information about the type of flux coating and specific characteristics of the rod. For instance:

- 7018 Rod: The "8" denotes a low-hydrogen rod with a basic flux covering.

- 6010 Rod: The "0" signifies a "fast freeze" rod with a cellulosic flux covering, ideal for out-of-position welding.

- 6011 Rod: The "1" indicates a rod similar to 6010 but designed for use with AC power sources.

For low-alloyed welding electrodes, the last digit may also specify alloy content, such as in E7018-A1, which contains 0.5% Molybdenum.

How to Choose the Right Welding Rod for Your Job?

What Are the Characteristics of Common Welding Rods?

Each welding rod has unique characteristics suited for different applications. Here are some commonly used rods and their features:

- 6010 Rod: Known for deep penetration and fast freezing puddle, ideal for dirty or rusty materials.

- 6011 Rod: Similar to 6010 but usable with AC, making it versatile for different power sources.

- 7018 Rod: Provides a smooth weld with minimal spatter and strong tensile strength, perfect for structural welding.

- 6013 Rod: Produces a soft arc and is easy to use, making it suitable for thin or sheet metal.

What Are the Pros and Cons of Common Welding Rods?

Understanding the advantages and disadvantages of each rod helps in selecting the best one for your project.

- 6010 Rod:

- Pros: Deep penetration, good for dirty/rusty surfaces.

- Cons: Requires more skill to handle, not suitable for AC.

- 6011 Rod:

- Pros: Versatile, usable with AC, good penetration.

- Cons: Higher spatter compared to 6010.

- 7018 Rod:

- Pros: High tensile strength, low hydrogen, smooth weld.

- Cons: Requires proper storage to prevent moisture absorption.

- 6013 Rod:

- Pros: Easy to use, low spatter.

- Cons: Less penetration, not ideal for thicker materials.

What Products Should You Consider?

When selecting welding rods, it's important to choose high-quality products from reliable sources. At WeldingMart, we offer a wide range of welding rods to meet your needs. Here are some recommended products:

- Lincoln Electric 7018 Welding Rods: Ideal for structural welding with high tensile strength.

- Hobart 6011 Welding Rods: Versatile and suitable for various power sources.

- Forney 6010 Welding Rods: Perfect for deep penetration and challenging surfaces.

Explore our welding rod selection for more options.

FAQ Section

What do welding rod numbers mean?

The numbers on a welding rod indicate its tensile strength, position usability, and specific characteristics or flux types.

How do I choose the right welding rod?

Consider the tensile strength, the positions you'll be welding in, and the type of flux covering needed for your project.

Can I use any welding rod for all positions?

No, only rods with a "1" in the third position number can be used in all positions.

Why is the last number on a welding rod important?

The last number indicates the flux covering type and specific characteristics, which affect the weld quality and application suitability.

What are the best welding rods for beginners?

Rods like 6013 are easier to use and produce low spatter, making them suitable for beginners.

2 comments

very useful and clear

excellent use for welding jobs