An engine-driven welder is the ideal solution for people who need a reliable welding rig that’s ready at a moment’s notice. These welders run on a gasoline, propane or diesel engine. They are usually are available with an electric generator to power work lights, fans, small air compressors and other electrical equipment.

-

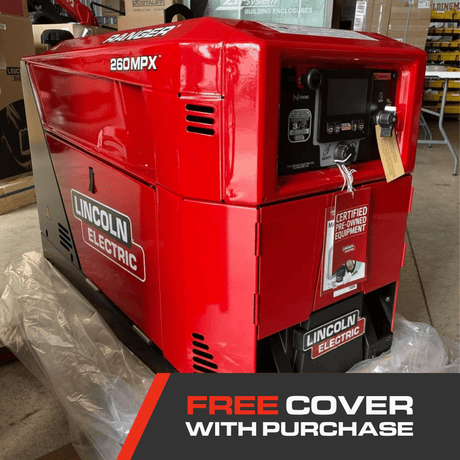

Lincoln Ranger Air 260MPX Multi-Function Engine Drive Low Hour Factory Demo Model - U5238-1

$12,300.00$16,994.00Unit price /UnavailableLincoln Bulldog 5500 Factory Demo Engine Driven Welder Kohler - U2708-2

$1,999.00$4,260.00Unit price /UnavailableLincoln Ranger 330MPX Low Hour Factory Demo Engine Driven Welder Generator Kohler - U3459-1

$8,399.00$9,849.99Unit price /UnavailableLincoln Ranger 330MPX EFI Low Hour Factory Demo Engine Driven Welder Generator Kohler - U4779-1

$8,999.00$10,689.99Unit price /UnavailableLincoln Factory Demo Ranger 305 LPG Engine Driven Welder Kohler - U2937-1

$9,299.00$11,459.99Unit price /UnavailableLincoln Factory Demo Maverick 325X Engine-Driven Welder Kubota - U3581-1

$15,999.00$20,281.00Unit price /UnavailableLincoln Vantage 322 Engine-Driven Low Hour Factory Demo Welder/Generator Kubota - U2409-5

$19,999.00$25,431.00Unit price /UnavailableLincoln Factory Demo Outback 185 Engine Driven Welder (Kohler) U2706-2

$4,799.00$6,219.99Unit price /UnavailableLincoln Eagle 10,000 PLUS Factory Demo Engine Driven Welder Kohler - U2343-3

$4,799.00$6,138.00Unit price /UnavailableLincoln Eagle 10,000 Plus Engine Drive Factory Demo Welder - U2343-4

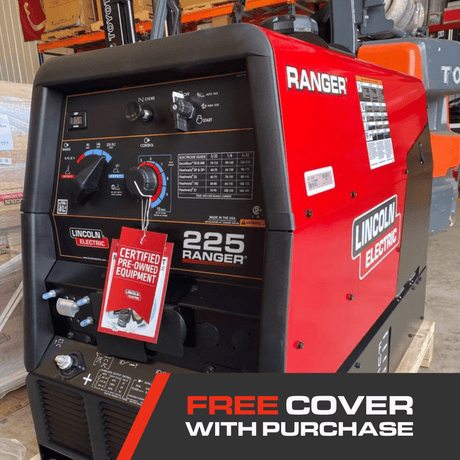

$4,899.00$6,573.80Unit price /UnavailableLincoln Ranger 225 Low Hour Factory Demo Engine Driven Welder Kohler - U2857-1

$5,699.00$6,849.99Unit price /UnavailableLincoln Ranger 250 GXT Low Hour Factory Demo Engine Driven Welder Kohler W/EFP - U2382-4

$6,499.00$8,829.99Unit price /UnavailableLincoln Ranger 260MPX Low Hour Factory Demo Engine Driven Welder - U3458-1

$6,899.00$8,129.99Unit price /UnavailableLincoln Ranger 305G Low Hour Factory Demo Machine - U1726-5

$8,235.00$10,323.00Unit price /UnavailableLincoln Factory Demo Ranger 305 G EFI Engine Driven Welder (Kohler) U3928-1

$8,950.00$10,045.00Unit price /UnavailableLincoln Maverick 260X Low Hour Factory Demo Model Welder/Generator Engine Drive - U5272-1

$12,799.00$16,996.00Unit price /UnavailableLincoln Ranger Air 330MPX Multi-Function Engine Drive Factory Demo - U5239-1

$14,699.00$18,022.84Unit price /UnavailableLincoln Frontier 400X Perkins Low Hour Factory Demo - U3484-1

$18,999.00$26,079.00Unit price /UnavailableLincoln Frontier 400X Low Hour Factory Demo Engine-Driven Welder Kubota - U3484-2

$21,499.00$26,838.00Unit price /UnavailableLincoln Factory Demo Frontier 400X Pipe Perkins Engine-Driven Welder/Generator - U3485-1

$21,699.00$26,378.00Unit price /UnavailableUsed Engine Driven Welders for Sale: Demo Units Available

An engine-driven welder is the ideal solution for people who need a reliable welding rig that’s ready at a moment’s notice. These welders run on a gasoline, propane or diesel engine. They are usually are available with an electric generator to power work lights, fans, small air compressors and other electrical equipment. As such, engine-driven welders are popular for contractors, mechanics, farmers, maintenance workers and other professionals who require on-demand welding reliability. These welders are capable of performing various welding processes, including MIG, stick, TIG, and flux cored welding, making them versatile tools for different applications.

Those who want the versatility of an engine-driven welder at a reduced price are encouraged to try the Lincoln Electric engine-driven welders we have in stock here at WeldingMart. When you pair the generous Lincoln-Kohler generator rebates with the free shipping we provide, these welders can be purchased at an absolute steal. Potential buyers can compare meter readings of different units to assess their usage and make informed purchasing decisions. Additionally, our listings come with an IronClad Assurance meter, ensuring the reliability and quality of the equipment. Lincoln also backs the welder with a three-year warranty for preconditioned machines, which is just another reason to shop Lincoln.

Reconditioned Welders at Discount Prices

Choosing used engine-driven welded machines lets you get all the features and performance of a new welder while saving hundreds, even thousands of dollars. Many of these welders were store demonstration models or overstock returned to Lincoln; as such, they have barely been used if at all. If the generator/welder was previously leased or rented, Lincoln Electric technicians have refurbished it, replacing broken or worn parts and thoroughly testing the unit to confirm it meets OEM standards.

Shop a large selection to fund the right used engine-driven welder for sale that your business needs. These reconditioned stick welders are a great choice for fabrication on thick materials and in outdoor environments; plug in a variety of accessories for MIG, TIG and flux-core welding. With EFI and diesel welder units offering a variety of power outputs, you can get a machine that will do everything from simple structural repairs to temporarily powering your house or shop in case of an electrical outage.

If you have any product or operational questions, don’t be afraid to give us a call or send us an email from our website. Our staff consists of highly skilled welders with years and years of experience who will be more than happy to assist you with anything you need. Remember that quantities are limited, so don’t hesitate at the chance to get a used welder/generator for sale from an industry leader.

Overview of Engine Driven Welders

Engine driven welders are a type of welding machine that uses an internal combustion engine to generate power for welding. Also known as portable welders or gas-powered welders, these machines are ideal for fieldwork and remote locations where access to electricity is limited. Engine driven welders eliminate the need for an external power source, providing mobility and flexibility. Our website displays page items efficiently, allowing you to navigate through multiple listings with ease. They are commonly used in construction, maintenance, and repair industries, offering a reliable solution for on-demand welding needs. Whether you’re working on a construction site or performing maintenance in a remote area, engine driven welders ensure you have the power you need to get the job done.

Benefits of Buying Used

Buying a used engine driven welder can be a smart, cost-effective alternative to purchasing a new one. These welders often provide reliable service at a fraction of the cost of new models. Additionally, opting for a used welder supports sustainability by reducing waste and extending the life of the equipment. When considering a used engine driven welder, it’s crucial to evaluate the machine’s condition, age, and maintenance history to ensure it meets your needs. Many used welders come with warranties or guarantees, offering added peace of mind. By choosing a used engine driven welder, you can save money while still achieving high-quality welding results.

Engine Driven Welder Options

Engine driven welders come in a variety of options to suit different needs and applications. Here are some common types:

-

Gasoline-powered welders: Ideal for fieldwork and remote locations where electricity is scarce.

-

Diesel-powered welders: Perfect for heavy-duty applications and long-term use, offering robust performance.

-

Propane-powered welders: A cost-effective alternative to gasoline-powered models, providing clean and efficient power.

-

Multi-process welders: Capable of performing multiple welding processes, such as MIG, TIG, and flux core, making them versatile tools for various tasks.

When selecting an engine driven welder, consider factors like power output, duty cycle, and fuel capacity to ensure the machine meets your specific requirements.

Featured Inventory

Our featured inventory includes a diverse range of engine driven welders from top manufacturers like Lincoln Electric and Miller. We offer:

-

New and used engine driven welders

-

Reconditioned and refurbished welders

-

Demo units and floor models

-

Welders with various power outputs and features

Our inventory is updated regularly, so be sure to check back often for new listings. We also provide asset appraisal services to help you determine the value of your used welder, ensuring you get the best deal possible.

Why Choose Us

When it comes to buying or selling engine driven welders, we are the trusted experts. Our team has years of experience in the welding industry and is dedicated to providing exceptional customer service. We offer:

-

Competitive pricing and flexible payment options

-

A wide range of new and used engine driven welders

-

Asset appraisal services to determine the value of your used welder

-

IronClad Assurance on select listings, providing added peace of mind

-

A user-friendly website with saved search and compare features

Visit our website today to explore our inventory and learn more about our services.

Engine Driven Demo Units Questions & Answers