Shop welding helmets and hoods from top brands like Lincoln Electric. Featuring auto-darkening lenses, superior safety, and comfortable designs, these helmets provide reliable protection and visibility for safer, more efficient welding.

-

Lincoln VIKING 3250D FGS Welding Helmet - K3540-3

$608.91$883.00Unit price /Unavailable -

Lincoln VIKING 1740 Matte Black Welding Helmet - K3282-3

$162.76$224.88Unit price /Unavailable -

Lincoln VIKING Industrial Passive Black Welding Helmet - K3371-1

$54.56$87.65Unit price /Unavailable -

Lincoln VIKING 3350 Daredevil Welding Helmet - K3683-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 3350 ADV Black Welding Helmet - K3034-5

$479.87$721.64Unit price /Unavailable -

Lincoln VIKING 2450 ADV Series Black Welding Helmet - K3028-5

$391.34$608.57Unit price /Unavailable -

Lincoln VIKING 3350 Code Red Welding Helmet - K4034-4

$494.30$748.00Unit price /Unavailable -

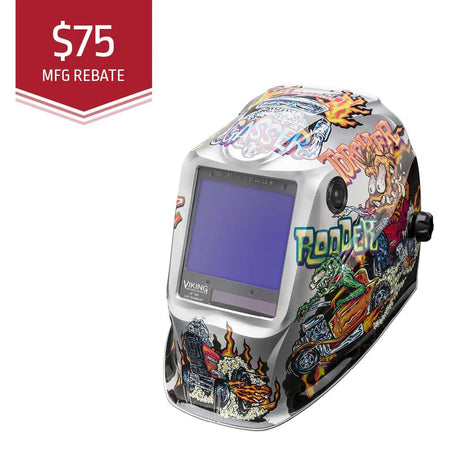

Lincoln VIKING 3350 Hot Rodders Welding Helmet - K4440-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 3350 Medieval Welding Helmet - K4671-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 3350 Mojo Welding Helmet - K3101-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 1740 ReCode Welding Helmet K3495-3

$184.88$264.00Unit price /Unavailable -

Lincoln VIKING 3350 Steampunk Welding Helmet - K3428-4

$494.30$748.00Unit price /Unavailable -

Lincoln VIKING 3350 All-American Welding Helmet - K3175-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 3350 Black Welding Helmet - K3034-4

$439.01$670.82Unit price /Unavailable -

Lincoln VIKING 2450 Heavy Metal Welding Helmet - K3029-4

$335.87$514.80Unit price /Unavailable -

Lincoln VIKING 1840 Series Black Welding Helmet - K3023-4

$318.36$478.98Unit price /Unavailable -

Lincoln VIKING 3350 White Tail Camo Welding Helmet - K4412-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 3350 Zombie Welding Helmet - K4158-4

$494.88$748.00Unit price /Unavailable -

Lincoln VIKING 2450 Street Rod Welding Helmet - K3035-4

$369.01$540.54Unit price /Unavailable -

Lincoln VIKING 2450 Black Welding Helmet - K3028-4

$367.87$545.00Unit price /Unavailable

Welding Safety Essentials: A Comprehensive Guide to Hoods and Helmets

1. Introduction to Welding Safety Gear

Why Welding Hoods and Helmets Are Crucial for Safety

Welding hoods and helmets, especially those by Lincoln and others from their Viking series like the VIKING 3350, are essential protective equipment for any welder. These Electric Welding Helmets provide top-notch protection for professionals or hobbyists. Lincoln Electric Welding helmets stand out as industry leaders in delivering reliable protection. Electric welding helmets offer reliable protection and meet industry safety standards. They shield the face, eyes, and neck from hazardous ultraviolet (UV) and infrared (IR) light, sparks, spatter, and intense heat generated during welding. Without proper head and face protection, welders risk severe injuries including burns, vision damage, and long-term health problems such as cataracts.

Using a quality welding hood or helmet can greatly reduce the chance of accidents and health complications, ensuring a safer and more efficient work environment. Electric helmets have been known for their outstanding performance in safety. Lincoln Electric Welding helmets are essential supplies for welders, incorporating advanced protective systems, including the cutting-edge VIKING 3350 model. This protection is not only a best practice but also required by safety standards across industries, solidifying their status as indispensable welding gear.

Overview of Types of Welding Hoods and Helmets

The market offers a range of welding hoods and helmets to fit different needs. Lincoln Electric leads the market with its state-of-the-art welding helmets, tools, and accessories, offering unmatched variety and quality. From traditional passive hoods to advanced auto-darkening welding helmets, including Lincoln Electric Welding models, each type serves specific applications and preferences with style. Understanding these options is key to selecting the right protective gear for your welding projects. Safety is the top priority when choosing a welding helmet.

2. Types of Welding Hoods and Helmets Products Overview

Passive Welding Hoods

Passive welding hoods feature a fixed, dark-tinted lens. They provide reliable protection and are favored for their durability and simplicity. Typically more affordable, passive hoods are ideal for straightforward welding tasks but do require welders to lift the hood to see between welds, which may impact efficiency and comfort during extended use.

Auto-Darkening Welding Hoods

Auto-darkening helmets, powered by advanced technology, have sensors that detect the welding arc and adjust the lens shade within milliseconds. This technology offers continuous visibility and protection, eliminating the need to raise or lower the hood frequently. Auto-darkening welding helmets improve workflow and reduce neck strain, making them a preferred choice among professional welders.

PAPR hoods are advanced systems that integrate helmet protection with respiratory safety, featuring Lincoln Electric models that excel in both areas.

PAPR hoods are advanced systems that integrate helmet protection with respiratory safety, featuring Lincoln Electric models. PAPR systems delivered by Lincoln enhance visibility and efficiency. PAPRs filter contaminated air, delivering clean airflow into the helmet while also shielding the welder from fumes, dust, and particulates. These hoods are essential for welding in environments with poor ventilation or hazardous materials.

The term welding helmets encompasses auto-darkening welding hoods and helmets. Lincoln's VIKING 3350 models are particularly distinguished for their new technology and improved systems that enhance visibility in various cutting processes.

Lincoln helmets include enhanced comfort, larger viewing areas, and unique features, often prioritized by users seeking top-notch protection. It is particularly well-suited for cutting applications, making it highly versatile. Lincoln offers a wide range of options to suit various welding applications. Helmets might feature enhanced comfort, larger viewing areas, or unique technologies, and are often favored by users seeking top-tier protection and versatility. Whether you need a helmet for TIG, MIG, or other welding processes, Lincoln has you covered with its innovative range.

3. Key Features to Consider

Lens Shade and Sensitivity Red Cover Lens

The lens shade is a critical aspect of welding helmets and hoods. It determines the level of darkness provided to the wearer’s eyes. Auto-darkening helmets may offer variable shade options, letting users select the optimal darkness for different welding processes. Sensitivity adjustments allow helmets to operate in various lighting environments and respond accurately to arc intensity. For welders involved in TIG or MIG processes, adjusting sensitivity is crucial for precision.

Weight and Comfort

Leather components add durability to the helmet's design. A welding hood or helmet’s weight directly affects wearer comfort, especially during prolonged use. Lightweight designs reduce fatigue, while features such as adjustable headgear and padded interiors enhance comfort and ensure a secure fit. It’s important to consider ergonomics and adjustability to maintain productivity and safety on the job. Black and Metal design elements can also contribute to both aesthetics and durability, and goggles are recommended for additional eye protection. Leather pads ensure a snug fit and add a layer of comfort during long hours of work.

Viewing Area and Safety Ratings

A larger viewing area facilitates better precision and work quality, giving welders a broader field of vision. An expanded viewing area is crucial for precision welding. Additionally, the VIKING 3350 series offers enhanced viewing areas. Safety ratings, such as ANSI Z87.1 certification, guarantee the helmet meets essential protective standards for impact resistance, light filtering, and overall durability. A helmet's shade control can enhance your welding experience. Always verify these ratings before purchasing to ensure reliable protection. Original Lincoln helmets are customized for individual needs. It's important to choose wisely among available cover lenses to fit your specific need.

Lincoln is an eminent brand in the welding equipment sector.

Lincoln Electric is renowned for its commitment to safety and innovation in the welding helmet industry, providing products that offer exceptional protection.

Their darkening welding helmets, including top models like Lincoln VIKING 3350, offer exceptional optical clarity and robust construction with options for accessories. Their welding helmets, including top models like the Viking series, are known for exceptional optical clarity, fast auto-darkening, and robust construction. Lincoln welding helmets are suitable for both demanding industrial jobs and personal welding setups. Its systems are tailored for cutting demands. Lincoln's Viking 3350 and VIKING 2450 series are top choices for any welding task.

Miller

Miller Electric is another trusted name, offering a range of welding hoods and helmets favored for comfort and innovative features. The Miller Digital Elite series, for instance, provides clear, customizable viewing and long battery life, catering to welders seeking high performance and reliability.

Hobart and Others

These helmets also feature leather headgear, which adds to the comfort and stability of use. Hobart, Jackson Safety, and 3M Speedglas are also prominent brands offering dependable welding helmets. Their helmets support high performance with the latest technology advancements, including auto-darkening functions and durable leather components. Exploring Custom options in helmets allows welders to select gear that fits their style and needs. Exploring multiple brands can help you find the perfect balance between quality, features, and budget.

5. Maintenance and Care for Welding Gear

Routine maintenance of welding helmets, including those from Lincoln, ensures a lasting performance.

Keep your Lincoln welding helmet’s lens and shell clean for optimal use. Use a soft cloth, mild soap, and water to wipe down the lens and shell. Avoid harsh chemicals that could damage interior coatings or electronics.

Maintain your helmet by securing Replacement lenses and parts when needed.

Over time, key components like lenses, batteries, or headgear may wear out. Most quality helmets offer easily replaceable parts. Keep spare lenses and batteries on hand, and consult your manufacturer’s recommendations for proper replacement intervals.

Safety Checks

Before each use, inspect your welding gear for cracks, compromised seals, or worn-out head straps. Proper maintenance and periodic safety checks are vital for ensuring consistent protection. If a component is damaged, repair or replace it immediately to avoid unnecessary risks.

Investing in the right welding hood or helmet—whether a Lincoln welding helmet, Miller, or another trusted brand—ensures protection, comfort, and efficiency for every weld. By understanding your options and prioritizing safety features and maintenance, you can make a smart choice and stay safe during all your welding tasks.

Welding Safety Essentials: A Comprehensive Guide to Hoods and Helmets

1. Introduction to Welding Safety Gear

Why Welding Hoods and Helmets Are Crucial for Safety

Welding hoods and helmets, especially those by Lincoln and others from their Viking series like the VIKING 3350, are essential protective equipment for any welder. These Electric Welding Helmets provide top-notch protection for professionals or hobbyists. Lincoln Electric Welding helmets stand out as industry leaders in delivering reliable protection. Electric welding helmets offer reliable protection and meet industry safety standards. They shield the face, eyes, and neck from hazardous ultraviolet (UV) and infrared (IR) light, sparks, spatter, and intense heat generated during welding. Without proper head and face protection, welders risk severe injuries including burns, vision damage, and long-term health problems such as cataracts.

Using a quality welding hood or helmet can greatly reduce the chance of accidents and health complications, ensuring a safer and more efficient work environment. Electric helmets have been known for their outstanding performance in safety. Lincoln Electric Welding helmets are essential supplies for welders, incorporating advanced protective systems, including the cutting-edge VIKING 3350 model. This protection is not only a best practice but also required by safety standards across industries, solidifying their status as indispensable welding gear.

Overview of Types of Welding Hoods and Helmets

The market offers a range of welding hoods and helmets to fit different needs. Lincoln Electric leads the market with its state-of-the-art welding helmets, tools, and accessories, offering unmatched variety and quality. From traditional passive hoods to advanced auto-darkening welding helmets, including Lincoln Electric Welding models, each type serves specific applications and preferences with style. Understanding these options is key to selecting the right protective gear for your welding projects. Safety is the top priority when choosing a welding helmet.

2. Types of Welding Hoods and Helmets Products Overview

Passive Welding Hoods

Passive welding hoods feature a fixed, dark-tinted lens. They provide reliable protection and are favored for their durability and simplicity. Typically more affordable, passive hoods are ideal for straightforward welding tasks but do require welders to lift the hood to see between welds, which may impact efficiency and comfort during extended use.

Auto-Darkening Welding Hoods

Auto-darkening helmets, powered by advanced technology, have sensors that detect the welding arc and adjust the lens shade within milliseconds. This technology offers continuous visibility and protection, eliminating the need to raise or lower the hood frequently. Auto-darkening welding helmets improve workflow and reduce neck strain, making them a preferred choice among professional welders.

PAPR hoods are advanced systems that integrate helmet protection with respiratory safety, featuring Lincoln Electric models that excel in both areas.

PAPR hoods are advanced systems that integrate helmet protection with respiratory safety, featuring Lincoln Electric models. PAPR systems delivered by Lincoln enhance visibility and efficiency. PAPRs filter contaminated air, delivering clean airflow into the helmet while also shielding the welder from fumes, dust, and particulates. These hoods are essential for welding in environments with poor ventilation or hazardous materials.

The term welding helmets encompasses auto-darkening welding hoods and helmets. Lincoln's VIKING 3350 models are particularly distinguished for their new technology and improved systems that enhance visibility in various cutting processes.

Lincoln helmets include enhanced comfort, larger viewing areas, and unique features, often prioritized by users seeking top-notch protection. It is particularly well-suited for cutting applications, making it highly versatile. Lincoln offers a wide range of options to suit various welding applications. Helmets might feature enhanced comfort, larger viewing areas, or unique technologies, and are often favored by users seeking top-tier protection and versatility. Whether you need a helmet for TIG, MIG, or other welding processes, Lincoln has you covered with its innovative range.

3. Key Features to Consider

Lens Shade and Sensitivity Red Cover Lens

The lens shade is a critical aspect of welding helmets and hoods. It determines the level of darkness provided to the wearer’s eyes. Auto-darkening helmets may offer variable shade options, letting users select the optimal darkness for different welding processes. Sensitivity adjustments allow helmets to operate in various lighting environments and respond accurately to arc intensity. For welders involved in TIG or MIG processes, adjusting sensitivity is crucial for precision.

Weight and Comfort

Leather components add durability to the helmet's design. A welding hood or helmet’s weight directly affects wearer comfort, especially during prolonged use. Lightweight designs reduce fatigue, while features such as adjustable headgear and padded interiors enhance comfort and ensure a secure fit. It’s important to consider ergonomics and adjustability to maintain productivity and safety on the job. Black and Metal design elements can also contribute to both aesthetics and durability, and goggles are recommended for additional eye protection. Leather pads ensure a snug fit and add a layer of comfort during long hours of work.

Viewing Area and Safety Ratings

A larger viewing area facilitates better precision and work quality, giving welders a broader field of vision. An expanded viewing area is crucial for precision welding. Additionally, the VIKING 3350 series offers enhanced viewing areas. Safety ratings, such as ANSI Z87.1 certification, guarantee the helmet meets essential protective standards for impact resistance, light filtering, and overall durability. A helmet's shade control can enhance your welding experience. Always verify these ratings before purchasing to ensure reliable protection. Original Lincoln helmets are customized for individual needs. It's important to choose wisely among available cover lenses to fit your specific need.

Lincoln is an eminent brand in the welding equipment sector.

Lincoln Electric is renowned for its commitment to safety and innovation in the welding helmet industry, providing products that offer exceptional protection.

Their darkening welding helmets, including top models like Lincoln VIKING 3350, offer exceptional optical clarity and robust construction with options for accessories. Their welding helmets, including top models like the Viking series, are known for exceptional optical clarity, fast auto-darkening, and robust construction. Lincoln welding helmets are suitable for both demanding industrial jobs and personal welding setups. Its systems are tailored for cutting demands. Lincoln's Viking 3350 and VIKING 2450 series are top choices for any welding task.

Miller

Miller Electric is another trusted name, offering a range of welding hoods and helmets favored for comfort and innovative features. The Miller Digital Elite series, for instance, provides clear, customizable viewing and long battery life, catering to welders seeking high performance and reliability.

Hobart and Others

These helmets also feature leather headgear, which adds to the comfort and stability of use. Hobart, Jackson Safety, and 3M Speedglas are also prominent brands offering dependable welding helmets. Their helmets support high performance with the latest technology advancements, including auto-darkening functions and durable leather components. Exploring Custom options in helmets allows welders to select gear that fits their style and needs. Exploring multiple brands can help you find the perfect balance between quality, features, and budget.

5. Maintenance and Care for Welding Gear

Routine maintenance of welding helmets, including those from Lincoln, ensures a lasting performance.

Keep your Lincoln welding helmet’s lens and shell clean for optimal use. Use a soft cloth, mild soap, and water to wipe down the lens and shell. Avoid harsh chemicals that could damage interior coatings or electronics.

Maintain your helmet by securing Replacement lenses and parts when needed.

Over time, key components like lenses, batteries, or headgear may wear out. Most quality helmets offer easily replaceable parts. Keep spare lenses and batteries on hand, and consult your manufacturer’s recommendations for proper replacement intervals.

Safety Checks

Before each use, inspect your welding gear for cracks, compromised seals, or worn-out head straps. Proper maintenance and periodic safety checks are vital for ensuring consistent protection. If a component is damaged, repair or replace it immediately to avoid unnecessary risks.

Investing in the right welding hood or helmet—whether a Lincoln welding helmet, Miller, or another trusted brand—ensures protection, comfort, and efficiency for every weld. By understanding your options and prioritizing safety features and maintenance, you can make a smart choice and stay safe during all your welding tasks.