Discover high-performance stud welders for fast, reliable fastening in construction, automotive, shipbuilding, and manufacturing. From capacitor discharge to drawn arc systems, our equipment delivers strong, precise welds with minimal distortion—ideal for a wide range of metal fastening applications.

-

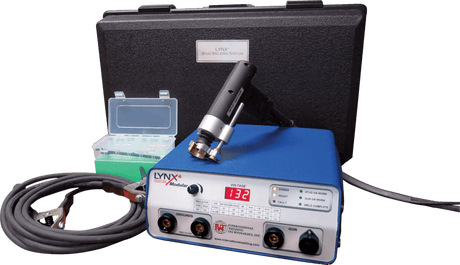

IWT LYNX4 Quickshot (1/4” Capacity) Stud Welding System - 1-IWT500054Q4

$2,999.00Unit price /Unavailable -

IWT LYNX4 Modular (5/16” Capacity) Capacitor Discharge Stud Welding System - 1-IWT500054M4

$3,300.00Unit price /Unavailable -

IWT LYNX4 Titan (3/8” Capacity) Stud Welding System with G-1 Gap Gun - 1-IWT500054T4G1

$5,199.00Unit price /Unavailable -

IWT LYNX4 Titan GFX (3/8” Capacity) Stud Welding System - 1-IWT500054T4GFX

$6,300.00Unit price /Unavailable -

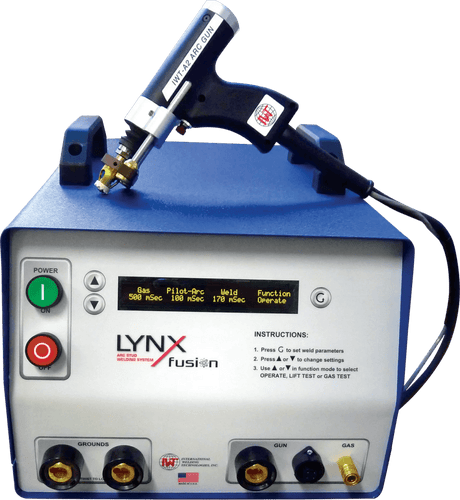

ITW - LYNX Fusion 1000 (1/2” Capacity) Stud Welding System - 1-IWT500055F

$6,900.00Unit price /Unavailable -

IWT LYNX Fusion 600 (3/8” Capacity) - 1-IWT500055F600

$6,000.00Unit price /Unavailable -

IWT ATLAS (Power Supply ONLY) - 1-IWT500054ATLAS

$6,500.00Unit price /Unavailable -

IWT LZ-4 Switch Box - 1-IWT500056L

$2,500.00Unit price /Unavailable -

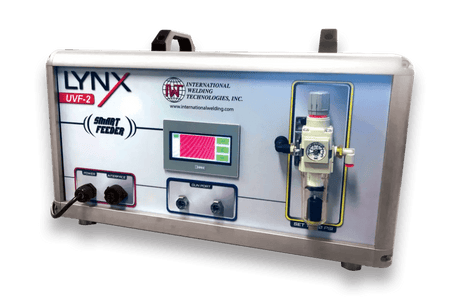

IWT UVF-2 Smart Feeder - 1-IWT500050

$12,000.00Unit price /Unavailable -

IWT LYNX Freedom Battery System (1/2” capacity) - 1-IWT500057

$10,500.00Unit price /Unavailable -

IWT - LYNX3 PIN WELDING SYSTEM - 1-IWT500046P

$3,295.00Unit price /Unavailable

Everything You Need to Know About Stud Welders

Introduction to Stud Welding

What Is Stud Welding?

Stud welding is a specialized fastening process where a metal stud or fastener is welded directly to another metal workpiece by using high heat, generated by an electric arc. Using high heat generated by an electric arc, the stud and the substrate are fused together in a matter of milliseconds. When using this method, various weld studs, such as those made of stainless steel, aluminum, and mild steel, are employed. This creates a highly durable bond that is both strong and reliable. Often used in different industries, stud welding has become the preferred technique for attaching fasteners like weld studs without requiring holes, bolts, or rivets.

Importance in Various Industries

The significance of stud welding spans a wide array of sectors. Construction, automotive, shipbuilding, and metal fabrication all benefit from its speed, reliability, and adaptability. The process is favored for its ability to create clean, strong joints without compromising the integrity of the base material. The standard stud welding process ensures a consistent and strong bond essential for construction and manufacturing. From attaching insulation pins to securing brackets, the versatility of stud welding has revolutionized how professionals approach metal fastening challenges. The quality of stud welding fasteners used significantly impacts the overall strength and reliability of the joined workpieces.

The Types of Stud Welding include Capacitor Discharge and Drawn Arc Stud Welding, each unique to specific applications.

Capacitor Discharge Stud Welding

Capacitor Discharge (CD) stud welding is a method that uses a short, high-intensity burst of electrical energy stored in capacitors. This technique is ideal for welding smaller-diameter studs to thin metal sheets without causing reverse marking or damage to the backside of the material. Applications for CD stud welding include electrical panels, enclosure fabrication, and automotive assemblies, where cosmetic appearance and speed are critical.

Key Features of CD Stud Welding: - Minimal thermal distortion - Fast welding cycles (milliseconds) - Suitable for thin and delicate materials

Drawn Arc Stud Welding

Drawn Arc stud welding is used for larger diameter studs and thicker materials. In this type of stud welding, the melting of the stud tip and base metal creates a strong bond as the stud is in place. This type offers excellent strength and is commonly utilized in structural steel fabrication, construction, and shipbuilding.

Key Features of Drawn Arc Stud Welding: - Strong, structural welds - Suitable for thicker materials and large studs - Often incorporates ceramic ferrules to contain the molten metal

Applications of Stud Welding

Industries That Utilize Stud Welding

Stud welding is prominent in: - Construction: Securing building components like insulation, shear connectors, and steel structures - Automotive: Fastening brackets, clips, and electrical components - Shipbuilding: Attaching decking, bulkheads, and supports - Manufacturing and Fabrication: Assembling appliances, electrical enclosures, and HVAC units

Typical Use Cases

Stud welding guns play a critical role in ensuring the precision and efficiency of the welding process. Real-world examples of stud welding applications include: - Attaching threaded studs for mounting parts without through-holes - Fixing insulation pins to HVAC ducts and panels - Connecting reinforcing bars (rebar) in concrete construction - Mounting electrical connectors in automotive panels

Choosing the Right Stud Welder

Factors to Consider

Selecting the right stud welder requires considering material type and thickness to ensure compatibility with your base metals and weld studs' required sizes. - Portability: Consider handheld or bench-top models for on-site or workshop use. - Power Requirements: Match welder output to your projects for optimal performance. Contact our representatives to discuss tailored solutions for your stud welding needs.

Top Brands and Models

Leading brands in the stud welding equipment market include: - HBS Stud Welding: Known for robust machines suited for industrial applications. - Nelson Stud Welding: Offers both portable and high-capacity systems for a range of industries. - TRAFIMET: Supplies versatile and reliable stud welding equipment for both CD and Drawn Arc techniques.

Benefits of Using Stud Welders

Efficiency, Precision, and Work Quality

- Time-Saving: Stud welding dramatically speeds up the fastening process compared to manual bolting or riveting.

- Consistency: Automated and semi-automated systems ensure uniform results, minimizing defects and rework.

- Quality: Produces strong, repeatable welds with minimal operator skill required.

Versatility in Use

- Adaptability: Handles various stud materials and diameters, making it usable across a spectrum of applications.

- Minimal Distortion: Advanced technology reduces heat-affected zones, safeguarding delicate or finished surfaces.

- Cost-Effective: By reducing labor and material input, stud welding contributes to lower overall project costs.

Stud welding remains a preferred choice for professionals in construction, automotive, and manufacturing, thanks to its efficiency, strength, and versatility, alongside high-quality equipment and Products. With advancements in equipment and technology, choosing the right stud welder has never been easier or more beneficial for modern industry needs.

Everything You Need to Know About Stud Welders

Introduction to Stud Welding

What Is Stud Welding?

Stud welding is a specialized fastening process where a metal stud or fastener is welded directly to another metal workpiece by using high heat, generated by an electric arc. Using high heat generated by an electric arc, the stud and the substrate are fused together in a matter of milliseconds. When using this method, various weld studs, such as those made of stainless steel, aluminum, and mild steel, are employed. This creates a highly durable bond that is both strong and reliable. Often used in different industries, stud welding has become the preferred technique for attaching fasteners like weld studs without requiring holes, bolts, or rivets.

Importance in Various Industries

The significance of stud welding spans a wide array of sectors. Construction, automotive, shipbuilding, and metal fabrication all benefit from its speed, reliability, and adaptability. The process is favored for its ability to create clean, strong joints without compromising the integrity of the base material. The standard stud welding process ensures a consistent and strong bond essential for construction and manufacturing. From attaching insulation pins to securing brackets, the versatility of stud welding has revolutionized how professionals approach metal fastening challenges. The quality of stud welding fasteners used significantly impacts the overall strength and reliability of the joined workpieces.

The Types of Stud Welding include Capacitor Discharge and Drawn Arc Stud Welding, each unique to specific applications.

Capacitor Discharge Stud Welding

Capacitor Discharge (CD) stud welding is a method that uses a short, high-intensity burst of electrical energy stored in capacitors. This technique is ideal for welding smaller-diameter studs to thin metal sheets without causing reverse marking or damage to the backside of the material. Applications for CD stud welding include electrical panels, enclosure fabrication, and automotive assemblies, where cosmetic appearance and speed are critical.

Key Features of CD Stud Welding: - Minimal thermal distortion - Fast welding cycles (milliseconds) - Suitable for thin and delicate materials

Drawn Arc Stud Welding

Drawn Arc stud welding is used for larger diameter studs and thicker materials. In this type of stud welding, the melting of the stud tip and base metal creates a strong bond as the stud is in place. This type offers excellent strength and is commonly utilized in structural steel fabrication, construction, and shipbuilding.

Key Features of Drawn Arc Stud Welding: - Strong, structural welds - Suitable for thicker materials and large studs - Often incorporates ceramic ferrules to contain the molten metal

Applications of Stud Welding

Industries That Utilize Stud Welding

Stud welding is prominent in: - Construction: Securing building components like insulation, shear connectors, and steel structures - Automotive: Fastening brackets, clips, and electrical components - Shipbuilding: Attaching decking, bulkheads, and supports - Manufacturing and Fabrication: Assembling appliances, electrical enclosures, and HVAC units

Typical Use Cases

Stud welding guns play a critical role in ensuring the precision and efficiency of the welding process. Real-world examples of stud welding applications include: - Attaching threaded studs for mounting parts without through-holes - Fixing insulation pins to HVAC ducts and panels - Connecting reinforcing bars (rebar) in concrete construction - Mounting electrical connectors in automotive panels

Choosing the Right Stud Welder

Factors to Consider

Selecting the right stud welder requires considering material type and thickness to ensure compatibility with your base metals and weld studs' required sizes. - Portability: Consider handheld or bench-top models for on-site or workshop use. - Power Requirements: Match welder output to your projects for optimal performance. Contact our representatives to discuss tailored solutions for your stud welding needs.

Top Brands and Models

Leading brands in the stud welding equipment market include: - HBS Stud Welding: Known for robust machines suited for industrial applications. - Nelson Stud Welding: Offers both portable and high-capacity systems for a range of industries. - TRAFIMET: Supplies versatile and reliable stud welding equipment for both CD and Drawn Arc techniques.

Benefits of Using Stud Welders

Efficiency, Precision, and Work Quality

- Time-Saving: Stud welding dramatically speeds up the fastening process compared to manual bolting or riveting.

- Consistency: Automated and semi-automated systems ensure uniform results, minimizing defects and rework.

- Quality: Produces strong, repeatable welds with minimal operator skill required.

Versatility in Use

- Adaptability: Handles various stud materials and diameters, making it usable across a spectrum of applications.

- Minimal Distortion: Advanced technology reduces heat-affected zones, safeguarding delicate or finished surfaces.

- Cost-Effective: By reducing labor and material input, stud welding contributes to lower overall project costs.

Stud welding remains a preferred choice for professionals in construction, automotive, and manufacturing, thanks to its efficiency, strength, and versatility, alongside high-quality equipment and Products. With advancements in equipment and technology, choosing the right stud welder has never been easier or more beneficial for modern industry needs.